OEM manufacturer Cold Glue Press Lcd Frame - HotBar Welding Machine For 5G High-Speed Cable QSFP Haba Soldering Jiutu – Jiutu

OEM manufacturer Cold Glue Press Lcd Frame - HotBar Welding Machine For 5G High-Speed Cable QSFP Haba Soldering Jiutu – Jiutu Detail:

HotBar Welding Machine For 5G High-Speed Cable QSFP Haba Soldering Jiutu

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

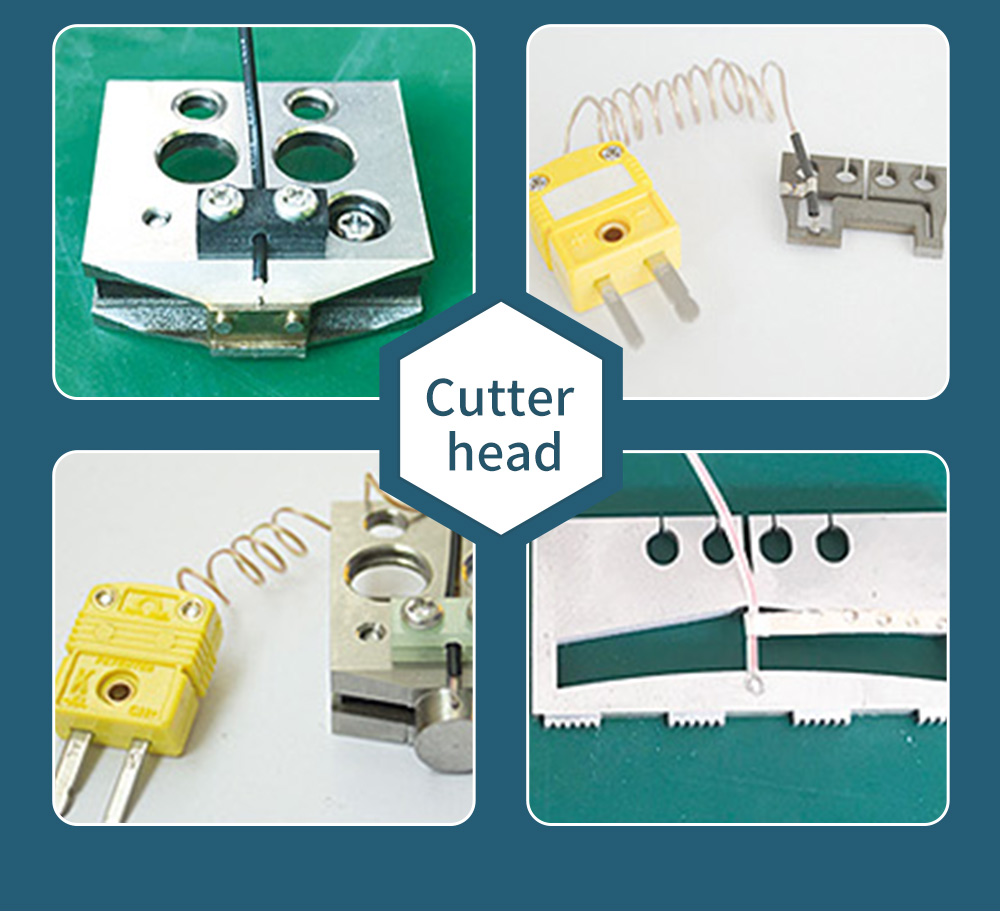

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Walmart’s Overpowered Gaming Laptop 17+ Review: Sam’s Choice, Not Ours | Industrial Robots

Global Assembly Machine Market Insights & Deap Analysis 2019-2024: EMAG GmbH, Bystronic Glass, STAUFF, AGME Automated Assembly Solutions | Front Glass With Frame

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for OEM manufacturer Cold Glue Press Lcd Frame - HotBar Welding Machine For 5G High-Speed Cable QSFP Haba Soldering Jiutu – Jiutu, The product will supply to all over the world, such as: Czech Republic , Irish , Hyderabad , With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!