China OEM Lcd Separator Screen Repair - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu

China OEM Lcd Separator Screen Repair - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu Detail:

Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering

Main Features :

1. This equipment adopts a pressure following mechanism to precisely control the pressure, and the welding products are fully dialyzed.

Working principle :

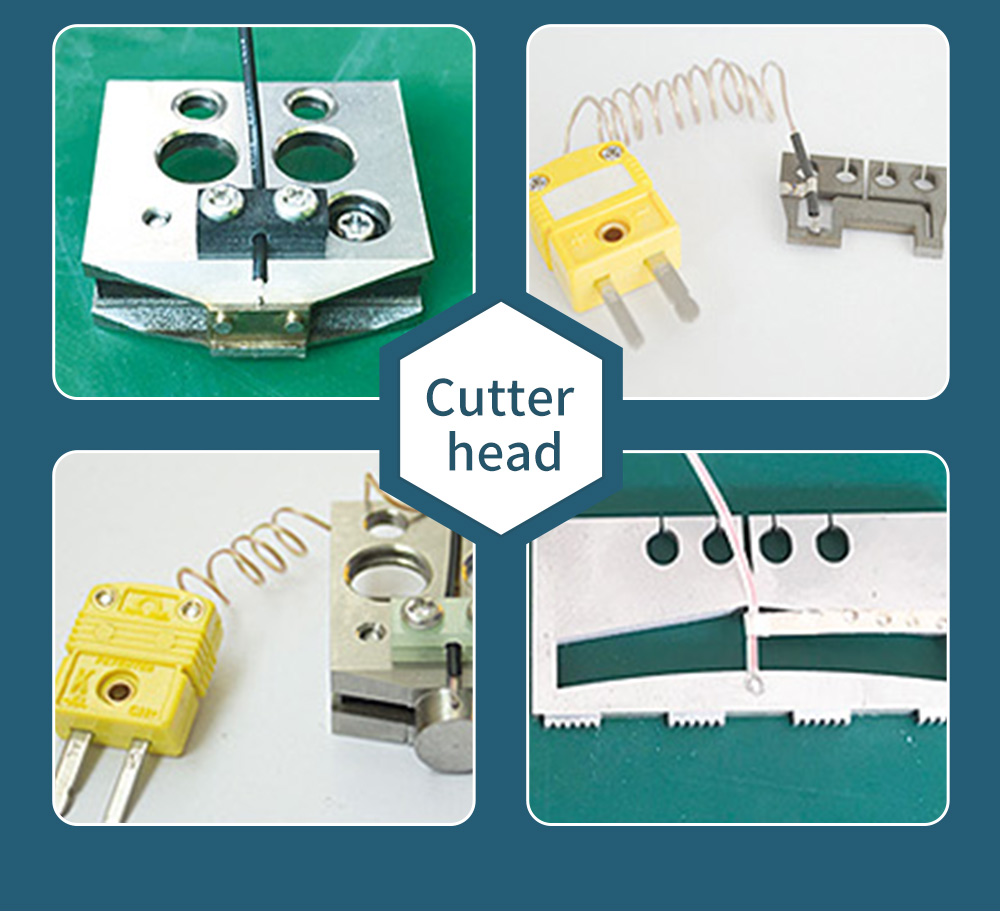

HotBar is usually a flexible board (FPC) soldered on the PCB, so that it can achieve the purpose of light, thin, short and small. In addition, the cost can be effectively reduced, because 1~2 flexible board connectors can be used less. The principle of the general HotBar hot press machine and the Haba machine is to use the huge Joule heat generated when a pulse current (pulse) flows through materials with high resistance properties such as molybdenum and titanium to heat the hot press head (thermodes/heater tip), and then borrow The solder paste already on the PCB is heated and melted by the thermal head to achieve the purpose of mutual welding. Since it is heated by pulse, the energy and time control of pulse is very important. The control method is to use the thermocouple circuit at the front end of the thermal indenter to feed back the temperature of the thermal indenter to the power control center in real time, so as to control the signal of the pulse. To ensure the correctness of the temperature on the thermal head.

Working area :

|

Model

|

HotBar Welding Machine

|

|

P/N

|

9TU-M039B

|

|

Heating Method

|

Pulse heating

|

|

Working Tempature

|

0℃ to 600℃

|

|

Working Humidity

|

40%–95%RH

|

|

Working Rated Power

|

2500W

|

|

Machine Size

|

64*55*57CM

|

|

Net Weight

|

85kg

|

|

Working Pressure

|

4–6kgf/cm2

|

|

Working Pressure

|

0.4-0.8Mpa

|

|

Volatge,Power Supply

|

220V 50Hz

|

Product detail pictures:

Related Product Guide:

Canon’s next full-frame mirrorless camera is the EOS RP Engadget Engadget save share save share save share save share save share save share Page 1 Page 1 ear icon eye icon Fill 23 text file vr | Air Bubble Removing Machine For Lcd Repair

Feather Brings Furniture Subscription To LA | PYMNTS.com Newly Funded Feather Brings Furniture Subscription To LA | Air Bubble Removing Machine For Lcd Repair

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for China OEM Lcd Separator Screen Repair - Precision PCB Heat Pressure Welding Machine For MINI SAS Line Pulse Heat Press Soldering – Jiutu, The product will supply to all over the world, such as: South Korea , Borussia Dortmund , South Korea , Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.